D-GLAZE

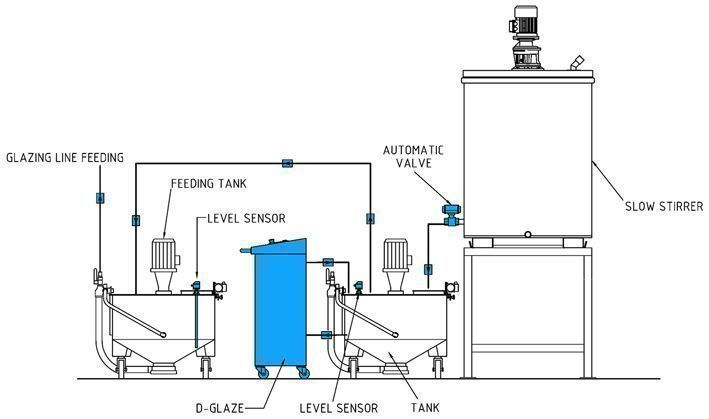

To have constancy in tonalities is very important to have always under control the base glaze applied before the digital decoration. Until now this was done with empirical methods, often based solely on experience and manual skills of the staff in line. To overcome these problems Smac has put on the market the model D-Glaze, an automatic system designed for the control of ceramic suspensions in an aqueous base (glazes) which require to be diluted and brought to a specific density before being used by any glazing machine. Ideal for the preparation and feeding of glazes basis for subsequent decoration with digital inkjet printers, D-Glaze allows to always have the desired amount of product and to maintain constant the set density thanks to automatic control devices at continuous cycle with automatic recirculation. The machine is designed to adapt to the existing equipment in the glazing line, thus avoiding the need to purchase new equipment and other dedicated to the device. The device can automatically controls the feeding of chemical additives.

Watch the video on Smac YouTube channel: D-GLAZE-AUTOMATIC DENSITY DEVICE (click here) GLAZING LINES AUTOMATION (click here)

Technical specifications

PRINCIPLE OF OPERATION:

When you start the cycle, the machine will fill the tank connected with the glaze to be diluted by taking it from the storage container through control of suitable pump. At the end of the filling procedure, the system begins to dilute the product with water by suitable cycles of addition / mixing until reaching the density set by the operator. Once reached the required density, the product is ready to be sent to the feeding tank of the using machine. By means of a level probe installed on user’s tank it is maintained monitored the quantity of product contained and when this falls below the minimum quantity, D-Glaze automatically provides to send the glaze to the correct density until reaching the maximum amount set. The enamel inside of the tank connected to the D-Glaze is kept under constant control by the electronic densimeter and suitably corrected in the case the density bait from the tolerance range set. The density is reduced by addition of water or increased by the addition of glaze taken from the storage tank. The cycle continues with this logic until the complete emptying, after which it restarts from the beginning.

D-GLAZE BENEFITS:

- Complete automation of glaze feeding to glazing machines and drastic stops reduction with consequent productivity increase and waste decrease

- Glaze density monitoring real-time done sent to the decorating machines and full automation of density correction with consequent elimination of eventual human errors in the process

- Avoid waste of glaze and tonal variations with significant savings in time and money. - Elimination of delays due to manual glaze preparation time and increase of the quality of the final product, thanks to a continuous electronic control

- Reduction of maintenance operations of the decorating machine. - Elimination of heavy operations: the staff will no longer come into direct contact with glazes and other potentially harmful products.

OPTIONAL:

Device for the automatic control of the viscosity of glazes, engobes and crystallines. The device is inserted inside D-Glaze and continuously monitors the viscosity value of the product. The value will be determined in centistokes (cSt)/centipoise (cP) and displayed on the operator panel. If this value deviates from the Set Point beyond the set tolerances, V-Check Evolution will notify the operator of the anomaly by means of an audible and visual alarm.